30 years ago this month, November 1983, J&D Machine started in the basement of our family home in New Hampshire. Back when we started, we only had a few cam machines and a cam shaper, and we did not know that we would become the successful CNC machining company we are today. 30 years later we only have CNCs (and a few more of them). In 1985 we moved into our first commercial space. We had 1250 square feet in our unit, and that’s when we added our first CNC machine. Back then we did a lot of electronics work as well as defense work. We stayed in that space for about 12 years and eventually tripled our space in 1997 when we purchased 3 identical units a few buildings over. This is where we still do business today. We currently have about 4000 square feet of manufacturing space, and 7 CNC machines. At our peak in 2009, just before the recession hit, we had 9 CNC machines.

Author: john

CNC Machining to 3D Printing

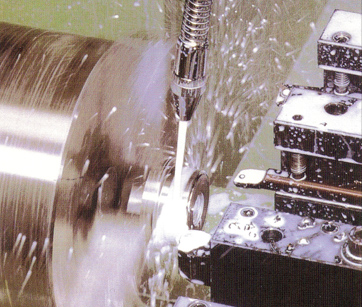

3D printing is becoming quite popular in the media these days. The idea that you can “print” something out of raw materials seems like something out of a science fiction movie, yet people are really doing it with this amazing technology. But what does it mean for the state of manufacturing? As I research about 3D printers I’m reminded of the changes in manufacturing that came about with the advent of CNC, or Computer Numerical Control. CNC changed manufacturing forever, making more complex parts a lot easier to create.

3D printing is somewhat of a natural progression from CNC turning and milling. In CNC, you’re starting with a rod of material and using tools on the X and Y axis, along with a moving Z axis to cut away the material until you have your desired shape. With 3D printing, you’re using the same X, Y and Z axes, but you’re putting down the material instead of taking it away, cutting the cost of tooling and fixturing.

But what will 3D printing do for CNC? I think it will improve it. There are already plenty of combination CNC machines and 3D printers, and since CNC shops are already used to CAD systems, I see the CNC shops that are heavy in prototyping adopting 3D printing and outfitting their shops with 3D printers.

3D printing is still in its infancy. Those who can remember back to the early 80’s, when CNC was just coming about might see some similarities between the two. 3D printing definitely has the same potential that CNC had back then.

When it comes to mass production, CNC is still the most cost effective and the fastest. Of course that could change because, as we know, anything is possible.

CNC Machining – Making Coke Machine Parts

When I was a little kid, I couldn’t wait for my dad to come home from work, so I could ask him what he made that day. More often than not, he would tell me he made coke machine parts. Imagine the pride I felt everytime I got a coke out of one of those big red machines. I would think, “My dad made parts for that. Cool.”

2013 – CNC Machining – Looking Ahead to the New Year

As we begin the year 2013, at J&D Machine, we are cautiously optimistic. With 2012 ending well in the CNC Machining world, in the hopes that 2013 will continue this way, we are making plans to add a new piece of equipment in the 2nd quarter. After our longest stretch of time without purchasing new equipment, we look forward to the process and seeing how much has changed in the last four years.

We have been working on some great new projects recently. CNC Machining projects that are small (but important) parts of exciting advances in robotics, defense, and aerospace. We are seeing a lot of new product quotes that we haven’t seen before, and that’s very encouraging.

Although nothing is etched in stone, this is a good sign that things are getting better in the CNC Machining industry, and we are excited to be a part of it.

Forging Relationships with Other Machine Shops

One of the best things you can do to grow a CNC machine shop is to develop long-lasting relationships with other machine shops. It’s important not to look at all the other businesses in your industry as competition, but as colleagues. Not only does it help to have support from the manufacturing community when you need it, but it’s also important to have trust in other machine shops that have different specialties when you need them. It’s difficult for a CNC machine shop to be good at absolutely everything. There are many jobs that we have to send out to our friends to make sure they are of the highest quality possible. We send out jobs for heat treating, grinding and plating, and we are lucky to have a few go to shops that we can trust with every job we send their way. Since turn-around time is usually stressed in our industry, we need to make sure that all our work is done right and on time every time. The bonus is that the work we send out is usually reciprocated when these shops get work in that requires one of our specialties, any small CNC turning or lathe CNC turning.

CNC Machining – A Small Part of a Big Deal

The Return of Cam Machines?

CNC Swiss – What Machine to Buy

Early on, when I was buying CNC Swiss, I felt best staying with one maker, but as we gained more experience with the constant pressure of needing to be ready for anything, we now have different makes of machines.

Tooling for CNC Swiss

I started my business in the mid 1980’s, and since then some things have changed as far as what is available for cutting tools used in CNC Swiss machines. Navigating the many choices is not always easy, but necessary to control costs. With every job you must decide which CNC swiss tools are the best fit.

There are many insert tools manufactured, but not all of them are a good fit for CNC Swiss. The size of the radius, the width of the tool, and the grind of the lead angle and rake are not the same for all manufacturers. If you have found a good one for you keep using it. If not try NTK, or Utilis. The real question is always when to use inserts and when to used braze carbide.

Before CNC Machining and CNC Swiss

Long before CNC machining, The s

With their unique features of a sliding head stock feeding into a solid guide bushing, they were able to produce tight tolerances and fine finishes with a high length of turn to diameter ratio. These cam driven automatic machines would become a major player in world wide manufacturing.